DGS and separation seal CobaSeal for a compressor

For the export compressor in a gas processing plant, EagleBurgmann developed a sealing solution based on DGS and CobaSeal that is more than just reliable. Low nitrogen requirement and minimal methane leakage reduce operating costs by a five-figure amount.

Compressor operating conditions: Suction pressure: p = 78 bar (1,131 PSI), Static pressure: p = 125 bar (1,812 PSI), t = 70 °C (158 °F), d = 200 mm (7.87"), n = 7,333 min-1, Medium: Natural gas/Methane

Read on for the entire case study

Sealing solution SHVI-CGSH for unmanned pump stations

Reduce maintenance costs for seal supply systems and extend MTBR intervals - EagleBurgmann significantly has improved the availability of unmanned pump stations in a gas pipeline in Texas with the single high-pressure seal SHVI and containment seal CGSH for multifluid pumps.

Read on for the entire case study...

Mechanical seal SHVI and Plan 66A for unmanned pump station

For the unmanned pump station of a Canadian oil pipeline, EagleBurgmann developed a single seal that can be used flexibly for several pump types and meets the highest safety requirements even up to 99 bar (1,436 PSI). The single seal SHVI with optimized Plan 66A is as safe as a double seal with buffer pressure system.

Read on for the entire case study...

Metal bellows seal MFLWTI and Plan 66A for a process pump

In processes with crude oil, seals in pumps are exposed to high temperatures and wear caused by solids. The safety standards are high to protect the environment and personnel from leaking media. For the process pump in a refinery EagleBurgmann developed a robust and reliable solution made of the metal bellows seal MFLWTI with DiamondFace coating and Plan 66A.

Read on for the entire case study...

Supply system RoTechBooster supports remote controlled operation of compressors

The supply of nitrogen for seals in compressors is particularly challenging in the Amazon region. The operator of a gas pipeline was looking for a low-maintenance yet reliable supply solution for two compressor stations in the middle of the Brazilian rainforest. The supply system RoTechBooster from EagleBurgmann fulfills the request of long maintenance intervals and reliable protection of the atmosphere from gas leakage

Read on for the entire case study...

Single seal HRS with DiamondFace for a multi-phase pump

Extra-heavy crude oil, sand, produced water and gas are the "living conditions" for the seals in a multi-phase pump in Venezuela. The EagleBurgmann single seal HRS with DiamondFace proved to be extremely robust despite a multiphase fluid and considerably less flush fluid.

Operating conditions: Suction pressure: p = 7.4 …9.1 bar (107 … 132 PSI), Outlet pressure: p = max. 16.5 bar (240 PSI), t = + 35 °C … + 40 °C (+ 95 °F … + 104 °C), n = 1,500 … 2,000 min-1, Medium: extra-heavy crude oil with 20-25 % solids content

Read on for the entire case study...

Shaft seals for screw compressors

Our dual seals of type LB800/EKU750 are applied on screw compressors.

Operating condition: p = 0.01 ... 5.7 bar (0.2 ... 82.6 PSI) ; t = 34.9 °C ... 205 °C (94.8 °F ... 401 °F) ; n = 1,859 ... 11,281 min-1. Medium: Gasified LNG with high percentage of methane.

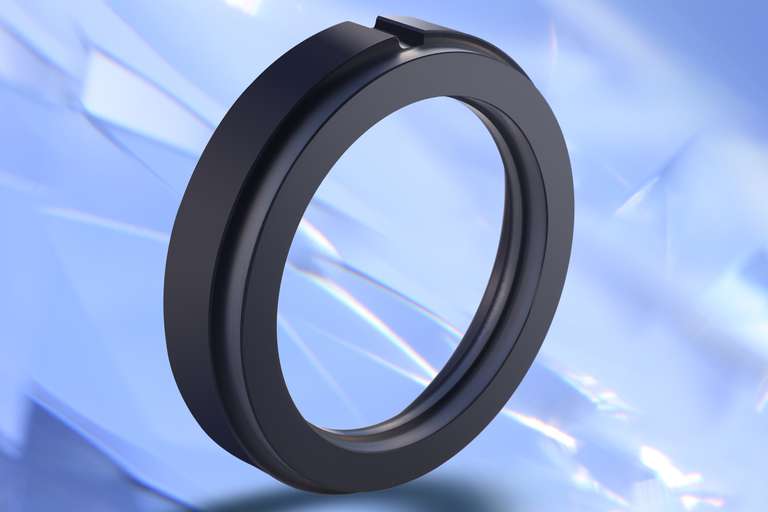

Wellhead seal for extreme conditions

A manufacturer of drilling equipment uses EagleBurgmann RX ring type joints, specially designed to withstand high pressures, in its wellheads. Media: drilling sludge, water/sand mixture, dihydrogen sulfide, natural gas, heavy hydrogen sulfide. The RTJ also provide reliable sealing in extreme conditions.

Operating conditions: p ... 1,370 bar (19,870 PSI); t ... 60 °C (140 °F).

Shaft seal in multiphase test circuit

A high pressure multiphase test circuit from Statoil in Norway is equipped with a Bornemann MPC pump with an EagleBurgmann SHFVI-D2/88-E1 dual seal and an API 53B supply system. Despite heavily fluctuating pressure conditions, the seal has never experienced any problems in active use.

Operating conditions: p1 = 10 ... 150 bar (145 ... 2,175 PSI); barrier fluid pressure: p3 = 160 bar (2,320 PSI); t = 60 °C (140 °F); n = 1,800 min-1.

Cartridge shaft seal for multiphase pump

In Western Siberia, Rosneft relies on an EagleBurgmann cartridge SH6/125-EF1 (API Plan 32) single seal to seal a Rosscar twin screw multiphase pump.

Operating conditions: Gas content ... 97 %; p ... 40 bar (580 PSI); t ... 65 °C (149 °F); n = 2,200 min-1.

Shaft seals for twin screw pump

In Venezuelas Zuata field, a Bornemann twin screw multiphase pump has been operating with EagleBurgmanns HSHJ97GS1/100-E1 (API Plan 32) single seal since 1998.

Operating conditions: Gas content ... 98 %; p ... 25 bar (363 PSI); t = 93 °C (199 °F); n = 1,660 min-1.

Hundreds of shaft seals in operation in twin screw pumps

CNRL in the Cold Lake region in Canada uses over 140 pumps with approximately 500 EagleBurgmann HSHJ92S1/80-E3 seals. The seals are fitted in Bornemann twin screw multiphase pumps. Operating conditions: Gas content ... 95 %; p ... 6 bar (87 PSI); t = 150 °C (302 °F); n = 1,200 min-1.

Shaft seals for helicoaxial multiphase pump

At Saudi Aramco in Saudi Arabia, an SHV-D2/145-E1 from EagleBurgmann is used as a dual seal in a helicoaxial multiphase pump from Sulzer.

Operating conditions: Gas content ... 99 %; p = 60 bar (870 PSI); t = 80 °C (176 °F); n = 4,000 min-1

Shaft seals for twin screw multiphase pump

In a pump station operated by Exxon Mobil in Africa, our SHV-D4/170-E1 (API Plan 54) functions as a dual seal for a twin screw multiphase pump from Leistritz.

Operating conditions: Gas content ... 99 %; p = 60 bar (870 PSI); t = 54 °C (129 °F); n = 1,200 min-1.

Safety hoods for fire extinguishing systems

In the Middle East, oil rigs and ships are equipped with safety hoods of type MA-1 as fireprotection devices for rubber expansion joints used in the fire extinguishing system and in pipelines to pump flammable liquids. The hoods have been certified for marine applications by Bureau Veritas

Exhaust expansion joints in oil production plants

EagleBurgmann Expansion Joints Solutions supplied several exhaust expansion joints with flanges for pipeline systems to a leading producer in Alaska, USA. The metal bellows joints are designed for temperatures up to 650 °C (1,200 °F) and for pressures from vacuum to 1.03 bar (15 PSI).

DiamondFace coated seals for gas oil pump

The gas oil separation process (GOSP) at Saudi Aramco in Saudi Arabia has been optimized with a Sulzer pump with vertically arranged sealing system for pumping the crude oil. Dry running of the pump at start-up frequently led to failure of the competitors seal. The operator then opted for EagleBurgmann single seal DF-HJ4S4 with DiamondFace coating of the seal faces.

Operating conditions: p = 6 bar (87 PSI); t = 22 °C ... 58 °C (72 °F ... 136 °F); n = 1,760 min-1.

Shaft seals for crude oil pipeline pumps

BTC (Baku Tbilissi Ceyhan) in Turkey has applied EagleBurgmann SHF3-D/135-E1 dual seals and the SHV-D3/170-E1 in the crude oil pipeline pumps provided by Ruhrpumpen GmbH.

Operating conditions: p = 1 bar (15 PSI); t = 5 °C ... 40 °C (41 °F ... 104 °F); n = 1,490 min-1; p = 74 bar (1,073 PSI); t = 30 °C (86 °F); n = 1,800 min-1.

Shaft seals for pipeline pumps

For the Greater Nile Petroleum Operating Company (GNPOC) in Sudan, a pipeline pump from Weir Pumps Ltd. is sealed using an EagleBurgmann SHFV1-D/125-E1 dual seal in conjunction with a SPN135/L003-D1 supply system.

Operating conditions: p = 46 bar (667 PSI); t = 75 °C (167 °F); n = 1,745 ... 3,850 min-1.

Shaft seal for sealing a twin screw pump

EagleBurgmann provided mechanical seals and a retrofitting concept for Petropiar/Ameriven (PDVSA Chevron Texaco) in Venezuela. The crude oil is now reliably sealed in a twin screw pump from Bornemann Pumps using an HSHJ47GS6/140-E1, despite the high viscosity.

Operating conditions: p ... 50 bar (725 PSI); t ... 60 °C (140 °F); n = 1,185 min-1.

DiamondFace coated shaft seal for Bornemann multiphase pumps

A DiamondFace-coated HSHJ4S1 was implemented in the Panacocha project in Ecuador. By diamond-facing both seal ring and mating ring it was possible to ensure that the sliding surfaces can withstand dry running for several inutes without damage, and even handle temperatures in the sealing gap of up to 300 °C (572 °F) without problems.

DiamondFace coated shaft seal for gas/oil multiphase

Originally, a competitors double seal with barrier fluid circulation system based on API Plan 54 was installed. This required a lot of maintenance. Following the retrofit using an SGR with unpressurized quench and a DiamondFace coating, the customer benefited from a significant, sustained reduction in maintenance and monitoring activity.

DiamondFace coated shaft seals for crude oil export pumps

The originally supplied seals had a service life of approx. three months and required a lot of maintenance. Main problem was dry running of the seals. EagleBurgmann solved this problem with its DiamondFace coated DF-HJ4S1 single seals in cartridge design.

Shaft seals for demanding oil pump application

EagleBurgmann was awarded a contract to provide hermetic sealing for four multistage vertical can pumps. The pumps are used to circulate highly flammable liquid hydrocarbons (C2 and C4).

Download the PDF for the full story.

Different shaft seals for ESPO pipeline project

The ESPO (East Siberia Pacific Ocean) pipeline operated by Transneft in Russia features EagleBurgmann SHPVI1-D dual seals in Sulzers pipeline pumps. The barrier fluid is not oil, but water. Sixty dual highpressure seals for the main pipeline pumps and 24 API Plan 53B barrier systems with airblast heat exchangers have been provided for the ESPO project.

Operating conditions: p = 10 ... 78 bar (145 ... 1,131 PSI); t ... 50 °C (122 °F); n = 1,540 ... 2,845 min-1

Another 64 single high pressure seals of type HRS8 with ZY203 cyclone separator are installed in booster pumps

Operating conditions: p = 5 ... 62 bar (73 ... 899 PSI); t = 15 °C ... 60 °C (59 °F ... 140 °F); n = 3,000 min-1

Hundreds of shaft seals for pipeline screw pumps

The pump stations along the 700 km pipeline which extends from the Sudanese oil fields of Baleela to Karthoum have 300 EagleBurgmann seals of type HJ4, in different versions, installed in Bornemann screw pumps. Suction pressure p = 4 ... 50 bar (58 ... 725 PSI); t = 29 ... 70 °C (84 °F ... 158 °F); n = 440 ... 1,240 min-1; viscosity of media: 990 ... 1,700 mm2/s.

Download the PDF for the full story.